Rubber Molding Services

Mil-Tek Rubber is your trusted partner in rubber molding solutions. With decades of expertise, we proudly serve clients across all 48 contingous states, delivering high-quality molded products tailored to your specific requirements.From compression and transfer molding to vulcanized extrusions, our capabilities encompass a wide spectrum of solutions designed to deliver exceptional quality and performance. Explore our versatile molding capabilities and discover how Mil-Tek Rubber can elevate your next project.

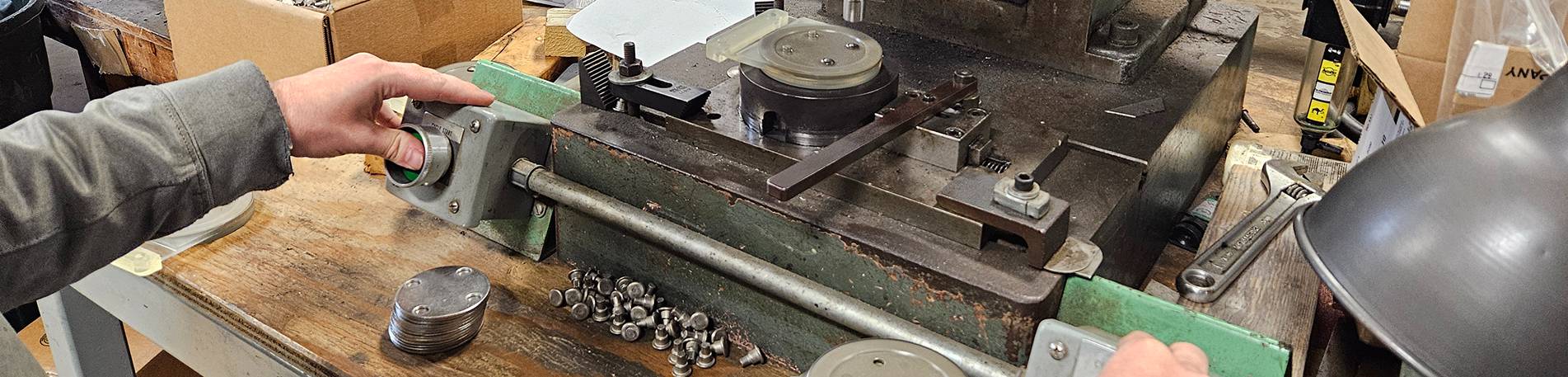

Die Cutting

We provide top-notch die cut gaskets crafted from various materials to meet our customers' specific requirements. We take pride in collaborating closely with our clients to thoroughly understand their processes and applications before moving on to the prototype phase. Our expertise lies in creating custom die cut solutions, including gaskets and seals. We serve a diverse array of industries, such as chemical, medical, automotive, aeronautical, marine, military, construction, industrial, and many others.

Compression Molding

We specialize in providing customized compression molding services to meet the unique requirements of our clients. Our extensive expertise ensures the efficient and cost-effective production of precise rubber parts tailored to your specifications. Whether you need simple seals or intricate grommets, our compression molding process is designed to deliver high-quality components with minimal scrap and defects.

Our compression molding capabilities offer versatility to accommodate a wide range of materials and part geometries, making it suitable for various industries and applications. We prioritize dimensional accuracy and tight tolerances in every part produced, ensuring consistency and reliability. Additionally, our commitment to sustainability is evident through our efforts to minimize material waste, reducing costs and environmental impact.

At Mil-Tek Rubber, we understand the importance of design flexibility in meeting our clients' evolving needs. Our compression molding process allows for the incorporation of inserts, reinforcements, and multiple material layers into molded parts, providing customized solutions to address specific application requirements. Trust us to deliver exceptional quality and durability in every compression molded part we produce.

Transfer Molding

We provide tailored transfer molding services to meet clients' needs efficiently and affordably. Our process produces a range of components with minimal waste and defects, from basic seals to complex grommets. With precise control over material flow, we ensure uniform distribution and high-quality parts with tight tolerances.

Our transfer molding process prioritizes sustainability by minimizing waste and optimizing production efficiency. It offers flexibility for incorporating inserts and reinforcements to meet specific requirements. Trust Mil-Tek Rubber for reliable and innovative solutions through our transfer molding services.

Compression Molding vs Transfer Molding

Both compression molding and transfer molding are viable manufacturing processes with their advantages and considerations. The choice between the two depends on the end-use, and what factors are most important to their application. The listed factors below may help your decision between the two.

- Material Distribution: Transfer molding offers more controlled material distribution compared to compression molding, resulting in higher precision and less material waste.

- Tooling Complexity: Transfer molding typically requires more complex tooling and equipment compared to compression molding, which can affect initial setup costs.

- Cycle Times: Transfer molding generally has shorter cycle times, making it more suitable for high-volume production environments.

- Part Complexity: While both processes can produce simple and complex parts, transfer molding may be preferred for parts requiring intricate details or thin walls due to its enhanced material flow control.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Rubber Molding Materials

Mil-Tek Rubber specializes in molding a diverse range of materials to meet various application requirements. Whether you need parts with excellent weather resistance, high temperature tolerance, oil and chemical resistance, or cushioning properties, we have the expertise to produce components that meet your specific needs. Our capabilities include molding with:

- EPDM

- Silicone

- Viton

- Nitrile

- Neoprene

- Urethane

Industries & Applications

Compression and transfer molding are versatile manufacturing processes used across various industries for a wide range of applications. Here are some common industries and applications for each process:

Compression Molding:

- Automotive: Seals, gaskets, O-rings, engine mounts, and vibration dampers.

- Aerospace: Gaskets, seals, vibration isolators, and aerospace components.

- Electronics: Insulators, gaskets, seals, and electrical connectors.

- Consumer Goods: Rubberized grips, buttons, knobs, and protective covers.

- Medical: Gaskets, seals, diaphragms, and medical device components.

- Industrial: Bushings, bumpers, washers, and industrial seals.

- Construction: Expansion joints, weather seals, and concrete molds.

- Energy: Seals, gaskets, and components for oil and gas applications.

Transfer Molding:

- Electronics: Encapsulation of electronic components, potting, and sealing.

- Automotive: Seals, gaskets, connectors, and sensor housings.

- Telecommunications: Encapsulated connectors, gaskets, and insulators.

- Medical: Encapsulated medical devices, gaskets, and seals for medical equipment.

- Industrial: Seals, gaskets, and insulators for various industrial applications.

- Consumer Goods: Encapsulated components for appliances, tools, and consumer electronics.

- Aerospace: Encapsulated sensors, connectors, and aerospace components.

- Energy: Encapsulated components for energy generation and transmission.